產品介紹

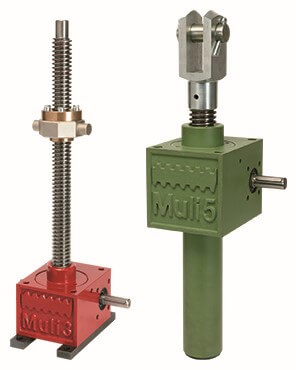

JUMBO® 1 - 5 (-500 kN)

Driven by a precision worm gearing (screw keyed to the worm wheel), the rotary motion of the screw is translated into linear motion of the travelling nut on the screw.

MULI® 0 - 5 (-100 kN)

The rotary motion of precision worm gearing (worm shaft and internally threaded worm wheel) is converted into axial linear motion of the screw, which travels through the gear box housing. The load is attached to the end of the screw.

Trapezoidal Screw Specifications:

| Trapezoidal Screws | MULI 1 | MULI 2 | MULI 3 | MULI 4 | MULI 5 | JUMBO 1 | JUMBO 2 | JUMBO 3 | JUMBO 4 | JUMBO 5 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Maximum Lifting Capacity (kN) | 5 | 10 | 25 | 50 | 100 | 150 | 200 | 250 | 350 | 500 | |

| Screw Diameter and Pitch (mm) | 18 x 4 | 20 x 4 | 30 x 6 | 40 x 7 | 55 x 9 | 60 x 9 | 70 x 10 | 80 x 10 | 100 x 10 | 120 x 14 | |

| Stroke in mm per full turn of drive shaft |

Ratio H | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Ratio L | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | |

| Gear Ratio | Ratio H | 4:1 | 4:1 | 6:1 | 7:1 | 9:1 | 9:1 | 10:1 | 10:1 | 10:1 | 14:1 |

| Ratio L | 16:1 | 16:1 | 24:1 | 28:1 | 36:1 | 36:1 | 40:1 | 40:1 | 40:1 | 56:1 | |

| Efficiency (%) | Ratio H | 31 | 29 | 29 | 26 | 24 | 23 | 22 | 20 | 19 | 19 |

| Ratio L | 25 | 23 | 23 | 21 | 19 | 18 | 17 | 15 | 15 | 15 | |

| Weight (kg) (zero stroke) | 1.20 | 2.10 | 6.0 | 17 | 32 | 41 | 57 | 57 | 85 | 160 | |

| Weight (kg per 100 mm stroke) | 0.26 | 0.42 | 1.14 | 1.67 | 3.04 | 3.10 | 4.45 | 6.13 | 7.90 | 11.5 | |

| Idling Torque (Nm) | Ratio H | 0.04 | 0.11 | 0.15 | 0.35 | 0.84 | 0.88 | 1.28 | 1.32 | 1.62 | 1.98 |

| Idling Torque (Nm) | Ratio L | 0.03 | 0.10 | 0.12 | 0.25 | 0.51 | 0.57 | 0.92 | 0.97 | 1.10 | 1.42 |

| Housing Material | G-AL | GGG-40 | |||||||||

Ball Screw Specifications:

| Ball Screws | MULI 1 | MULI 2 | MULI 3 | MULI 4 | MULI 5 | JUMBO 3 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Maximum Lifting Capacity (kN) | 5 | 10 | 12.5 | 22 | 42 | 65 | 78 | ||||

| Screw Diameter and Pitch (mm) | 16 x 5 | 20 x 5 | 25 x 5 | 40 x 5 | 40 x 10 | 50 x 10 | 80 x 10 | ||||

| Stroke in mm per full turn of drive shaft |

Ratio H | 1.25 | 1.25 | 0.83 | 0.71 | 1.43 | 1.1 | 1 | |||

| Ratio L | 0.31 | 0.31 | 0.21 | 0.18 | 0.36 | 0.28 | 0.25 | ||||

| Gear Ratio | Ratio H | 4:1 | 4:1 | 6:1 | 7:1 | 9:1 | 10:1 | ||||

| Ratio L | 16:1 | 16:1 | 24:1 | 28:1 | 36:1 | 40:1 | |||||

| Efficiency (%) | Ratio H | 57 | 56 | 55 | 53 | 56 | 47 | 45 | |||

| Ratio L | 46 | 44 | 43 | 43 | 45 | 37 | 34 | ||||

| Weight (kg) (zero stroke) | 1.3 | 2.3 | 7 | 19 | 35 | 63 | |||||

| Weight (kg per 100 mm stroke) | 0.26 | 0.42 | 1.14 | 1.67 | 3.04 | 6.13 | |||||

| Idling Torque (Nm) | Ratio H | 0.04 | 0.11 | 0.15 | 0.35 | 0.84 | 1.32 | ||||

| Idling Torque (Nm) | Ratio L | 0.03 | 0.10 | 0.12 | 0.25 | 0.51 | 0.97 | ||||

| Housing Material | G-AL | GGG-40 | |||||||||

Worm Gear Screw Jack Features:

- MULI® and JUMBO® series are manufactured for loads from 5 to 500 kN

- Cubic housing, standardized mounting material and end-pieces, and pre-drilled flange holes permit easy installation of motor, gears, and shaft encoder

- All models designed for tensile and compressive loads

- Complete range of motors and accessories is available

- All models designed for pushing forces, pulling forces, and for position independent functioning

- High and low speeds available due to two different ratios

- Synchronization of several screw jacks is easily accomplished

Worm Gear Screw Jack Options:

- Version N- screw rotation prevented by its permanent attachment to guided load

- Version V- anti-rotation device; recommended when screw jack cannot be secured externally to prevent rotation

- Version R- rotatory motion of the screw jack is translated into linear motion via travelling nut Note: nut must be purchased separately

- Gear Ratio H- one full turn of the shaft produces a stroke of 1 mm

- Gear Ratio L- one full turn of the shaft produces a stroke of 0.25 mm

未找到所需的絲杠螺旋升降機?聯系我們 獲取定制解決方案。

Family

尺寸

種類

Ratio

絲杠類型

Stroke

Screw End

End Fitting

Bellows

Nut

Stop Collar

Special Features

Screw Dimensions

比較

3D 模型

Family

- MULI - Lifting capacities up to 100 kN

- JUMBO - lifting capacities from 150 kN to 500 kN

尺寸

種類

Rotating Screw - R

The rotary motion of precision worm gearing (worm shaft and internally threaded worm wheel) is converted into axial linear motion of the screw, which travels through the gear box housing. The load is attached to the end of the screw.

Rotating Nut, with or without anti-rotation (axial translating Screw) - N or V?

Driven by a precision worm gearing (worm shaft and worm wheel), the rotary motion of the screw is translated into linear motion of the travelling nut on the screw.

Ratio

High Speed - One full turn of the worm shaft leads to a stroke of one millimeter.

Low Speed - One full turn of the worm shaft leads to a stroke of 0.25 mm.

絲杠類型

- Ball Screw (KGS) - For longer duty cycles, higher efficiency, high positioning accuracy

- Trapezoidal Screw (TGS) - For tough conditions, good price/performance ratio.

Stroke

The stroke length of the screw jack.

Screw End

Machining that is done to the end of the screw

- Standard Screw End (only for rotating nut) (G) – the end of the screw is machined to fit a standard end fitting.

- Cylindrical end (only for rotating screw) (Z) – the end of the screw is machined to a cylindrical shape

- No End machining (0) – End of the screw is cut to length. No machining is added.

- Special to customer specifications (S) – End of screw is machined to a customer provided specification

End Fitting

- No end Fitting (00) – Standard for rotating screw versions.

- Top Plate (BP)

- Fork End (GA)

- Clevis End (GK)

Bellows

Bellow cover for protection against external influences. Suitable for horizontal or vertical installation.

Nut

- Without Nut (0) – Always fro version rotating nut (N or V)

- Trapezoidal nut (1) – for rotating screw (R) with trapezoidal screw (TGS)

- Flanged ball nut (2) – for rotating screw (R) with ball screw (KGS). Flange of nut towards end of screw standard.

- Cylindrical ball nut (3) – for rotating screw (R) with ball screw (KGS)

Stop Collar

- With Stop collar (A) – Collar to stop the screw from being translated out of the nut. Fitted as standard on ball screw versions N and V. Optionally available for screw jacks with trapezoidal screws. The stop collar cannot be used as a fixed stop.

- Without stop collar (0) – always on rotating screw (R). Optional on rotating nut versions (N and V).

Special Features

- Without (0) – No special features

- Standard (Z) – With some standard accessories added. These are not captured in the part number

- Custom (S) – Special features as described by the customer

Screw Dimensions

The diameter and lead of the screw used. On most units there is only one choice per size and type. On Muli 4 there are 2 different ball screw choices.

- KGS 4005 (1)

- KGS 4010 (2)

All others leave this position in the part number blank.

Customer Service

This part number is not available for sale online but may still be available for sale. Click here to contact Thomson Customer Support.

Customer Service產品目錄

| Worm Gear Screw Jacks Muli®, Jumbo® | 5173 KB | |

| Worm Gear Screw Jacks Muli®, Jumbo® | 5230 KB | |

| Worm Gear Screw Jacks Muli®, Jumbo® | 5375 KB |

| ?MULI & JUMBO絲杠直線推桿 - N型 | |||

| MULI & JUMBO Screw Jacks - Type N - TGS |  |

— | — |

| MULI & JUMBO Screw Jacks - Type N - KGS |  |

— | — |

| MULI & JUMBO Screw Jacks - Type R | |||

| MULI & JUMBO Screw Jacks - Type R - TGS |  |

— | — |

| MULI & JUMBO Screw Jacks - Type R - KGS |  |

— | — |

| MULI & JUMBO Screw Jacks - Type V | |||

| MULI & JUMBO Screw Jacks - Type V - TGS |  |

— | — |

| MULI & JUMBO Screw Jacks - Type V - KGS |  |

— | — |